ldpe autoclave vs tubular|ldpe material types : import Gela Plant (Italy) 130 - LDPE 1981 Umm Said Plant (Qatar) 180 - LDPE 1996 Dunkerque Plant (France) 240 – LDPE/EVA 2011 (Autoclave converted to tubular) Location Capacity (kt/y) 1st start up date Gela Plant (Italy) 70 - LDPE 1963 Ferrara Plant (Italy) 110 - LDPE 1976 Maracaibo Plant (Venezuela) 70 - LDPE 1976 Bratislava Plant (Slovakia) 90 . American Autoclave Company 7819 Riverside Road E., Sumner, WA. 98390 .

{plog:ftitle_list}

The AMSCO 400 Series Small Steam Sterilizer (autoclave) provides efficient sterilization for .

Figure 3.3 shows a comparison between the tubular grades and the most common autoclave grades for extrusion coating 2404AN00 (MFR: 4.2 g/10min), 1808AN00 (MFR: 7.5 g/10min) .

Good control on molecular properties, and as a consequence on end-use properties, is very important for low-density polyethylene (LDPE) manufacturers. However, the connection between the architecture of polymer chains and the kinetic mechanism and polymerization conditions is still a subject of study. In this work, we present a comprehensive .of low density polyethylene (LDPE) and ethylene vinyl acetate (EVA) copolymers. The Lupotech T process is the leading high pressure tubular reactor technology for the production of LDPE and standard EVA, while Lupotech A is the high-pressure autoclave reactor process technology for the production of specialty LDPE, EVA copolymers with very

Autoclave vs. Tubular LDPE Current knowledge: • Broad MMD and LCB is essential for NI and web stability • Typical Autoclave grade behaviour; Low NI, stable film web r a l ubu Tl ac i py•T grade behaviour; Large NI, unstable film web chill roll film web die Extruder. 1.3 Paper 7651 Marcel Neilen 11Gela Plant (Italy) 130 - LDPE 1981 Umm Said Plant (Qatar) 180 - LDPE 1996 Dunkerque Plant (France) 240 – LDPE/EVA 2011 (Autoclave converted to tubular) Location Capacity (kt/y) 1st start up date Gela Plant (Italy) 70 - LDPE 1963 Ferrara Plant (Italy) 110 - LDPE 1976 Maracaibo Plant (Venezuela) 70 - LDPE 1976 Bratislava Plant (Slovakia) 90 .

Polymer Testing 9 (1990) 341-351 Morphological Characterization of Autoclave and Tubular LDPE by High Temperature IR Spectroscopy* G. C. Pandey, B. P. Singh & A. K. Kulshreshtha$ Research Centre, Indian Petrochemicals Corporation Ltd, Vadodara-391 346, Gujarat, India (Received 6 January 1990; accepted 19 April 1990) ABSTRACT High temperature IR . LDPE can be produced by different types of autoclave or tubular reactors, which can also be cascaded. An important effort is to obtain materials with autoclave-process equivalent properties from tubular technology due to economic reasons. In this way, the molecular understanding of the materials attains a key role.shows the simplified industrial production of LDPE using autoclave reactor (left) and tubular reactor (right). Autoclave reactor is a stirred cylindrical reactor typically about 6.1 m long and 0.38 - 0.91 m in diameter. Tubular reactor is similar to a tube or long pipe which usually about 1.25 km long and 2.5 - 7.6 cm in diameter. The tubular reactors operate at pressure up to 3,000 bar, whereas Autoclave reactor operates below 2,000 bar. MI range: 0.2 – 150 . Product from the tubular process is typically higher in molecular weight and has more short chain branches than LDPE from the autoclave process . Produce LDPE homo-polymers and ethylene vinyl acetate (EVA .

While most of the newly installed LDPE/EVA capacities are based on tubular reactors, autoclave reactors are still relevant, especially for producing specialty-grade EVAs. This report reviews the technology and evaluates the process economics for producing EVAs with a high-pressure autoclave reactor process and a high-pressure tubular reactor .

Autoclave Tubular Figure 1: Normalized molecular weight distribution plots for an autoclave and a tubular LDPE resin. The conformation plot shows the mean radius of gyration as a function of the molecular weight. Figure 2 shows an example for a HDPE, an autoclave LDPE and a tubular LDPE. The typical upward curl below 105 g.mol-1 is an For tubular processes, estimates are developed for LDPE and EVA (18% VA), while for autoclave processes, estimates are developed for LDPE and EVA (18% VA and 28% VA). In each region, the technology (tubular versus autoclave) employed affected the relative cost of production. View table of contentsAutoclave vs. Tubular LDPE: A Thai Perspective 🇹🇭 In the world of Low-Density Polyethylene (LDPE), two primary production processes dominate: Autoclave and Tubular. These processes give LDPE .

LDPE was discovered by ICI in 1933 →autoclave process in 1938 BASF developed the first tubular process during WW II High variation of autoclave and tubular processes by different licensors Nowadays licences available up to 400 kt/y plant capacity Consumption in 2015 –Global: 20,5 million t –Domestic: 60-65 thousand t MPK (TVK) LDPE plants

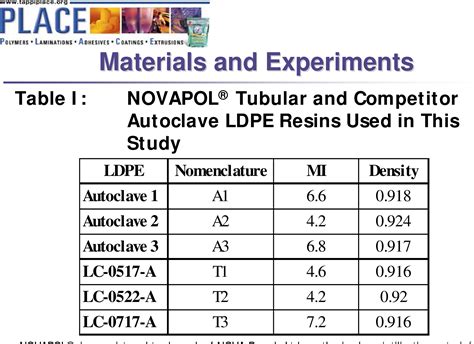

Autoclave vs. Tubular Process Autoclave Conversion up to 21% - adiabatic, reaction heat removed by reactant only 1300-2000 bar operating pressure Higher capacity of hyper compressor Organic peroxide initiators only Specialty polymer capability – EVA copolymers over 40% vinyl acetate Lower reactor capacity – 150 kt/y Tubular This paper discusses the general chemical and rheological differences between autoclave and tubular LDPE resins then focuses in more detail on those differences for a variety of tubular LDPE .Lo w-densit y p oly eth ylene (LDPE) is without a doubt one of the most widespread p olymers w orldwide. Its ann ual pro duction is estimated at 24 million tonnes and it is used for a large n um b er of applications, e.g., pac kaging, adhe-siv es, insulators, coatings and lms. Most of the LDPE is no w ada ys pro duced in tubular reactors, whic .LDPE Tubular reactor vs Autoclave reactor: Autoclave reactor: -- conversion up to 21% --adiabatic, reaction heat removed by reactant --1300--2000bar operating pressur --Higher capacity of .

of LDPE product mix than industry competitors in the Americas Autoclave vs Tubular LDPE: • Autoclave LDPE is a more specialty product with broader applications and better margins; Westlake’s focus into food packaging applications provides demand stability. • Supply/demand balance for autoclave grows tighter. Source for both charts: IHS Markit Low density polyethylene is commonly produced in highpressure autoclaves and tubular reactors. From the 90's on, when the majority of LDPE (60 %) was produced in the autoclave reactors, the tubular reactors gradually got the upper hand. Nowadays the tubular reactor stands for 60 % of the total production of LDPE.Possibilities of autoclave LDPE process Supervisor (Arcada): Rene Herrman Commissioned by: Ismo Savallampi, Borealis Polymers Oy Abstract: This thesis was written to find what different polyethylene plastic variants can be produced in an already built LDPE autoclave. More specifically, the whole process window of the

yellow tips/ yellow pipette tips

controlled by IR or GC) is compressed by large ethylene/polyethylene system. Hence one has ring-type piston compressors (or packed pis- single-phase bulk polymerization taking place, tons, diaphragm types) in two stages with The mixture is polymerized either in tubular intermediate cooling, to about 1000-3000 atm. reactors or in stirred autoclaves: The detailed stochastic simulation is used as add-on and offers a deep insight into the polymeric microstructure of each macromolecule. Our hybrid simulation approach is applied to high-pressure ethylene polymerization in industrial tubular and continuous autoclave reactors with peroxide initiation. Large-scale tubular reactors with a capacity in the range of 130,000 tpy–425,000 tpy, as well as stirred autoclave reactors with capacity around 125,000 tpy can be used. Description: A variety of LDPE homopolymers and copolymers can be produced on these large reactors for various applications including films, molding and extrusion coating. A commercial low-density polyethylene (LDPE) which is produced by the polymerization process of ethylene in the presence of initiators in a long tubular reactor is the most widely used in polymer .

Product from the tubular process is typically higher in molecular weight and has more short chain branches than LDPE from the autoclave process . Produce LDPE homo-polymers and ethylene vinyl acetate (EVA) copolymers; Source: Echem Enppi, Apr 2013, Polyethylene Production Technologies, via the Internet Archive. Computational fluid dynamics (CFD) is used in this study to model low-density polyethylene (LDPE) tubular and autoclave reactors. A polymerization reaction model is developed using the method of moments. The model includes six steps: initiator decomposition, chain initiation, propagation, chain transfer to monomer, disproportionation termination, and .on low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) [1]. LDPE is produced by free-radi-cal polymerization in tubular or autoclave reactors at temperatures up to 300 C and pressures up to 3000bar. The polymerization is started by a thermal initiator like an organic peroxide. By stepwise adding monomer to the

qenos autoclave ldpe

$869.99

ldpe autoclave vs tubular|ldpe material types